Automotive

/Home & Leisure

Toyota is investing $1.4 billion to build another all-electric SUV in US

Toyota Motor Corp. is moving ahead with plans to manufacture and sell more electric vehicles in the U.S. by investing $1.4 billion at a plant in Indiana, the Japanese carmaker’s second such announcement this year.

The Princeton, Indiana, facility — which currently makes four gas and hybrid models — will add an unnamed all-electric, three...Read more

Ford Q1 profits fall 28% as Ford Blue hit from F-150 ramp-up

Ford Motor Co. said Wednesday it made $1.3 billion in net income in the first quarter of 2024, a 28% decrease year-over-year, as earnings from Ford's gas-engine and hybrid business tumbled from the ramp-up of the refreshed 2024 F-150 pickup truck.

The profit that represented 33 cent earnings per diluted share came on $42.8 billion in revenue, ...Read more

GM's CEO no longer highest paid Detroit auto executive

General Motors Co. CEO Mary Barra is no longer the highest-paid Detroit automotive company chief executive, receiving a 2023 compensation package totaling $27.8 million — trailing Stellantis NV CEO Carlos Tavares' $39.491 million payout.

Barra, 62, saw her pay drop 4% from her 2022 compensation of $28.97 million with a decline in her bonus ...Read more

Tesla soars as Musk's cheaper EVs calm fears over strategy

Tesla Inc. shares surged after Elon Musk vowed to launch less-expensive vehicles as soon as late this year, easing concerns about disappointing earnings results and diminished growth prospects.

The automaker said Tuesday it’s accelerating new models using aspects of a next-generation platform that had been slated for the second half of next ...Read more

GM beats profit expectations in first quarter, increases guidance for 2024

General Motors Co. beat Wall Street expectations on Tuesday, delivering first-quarter net income of $3 billion on revenue of $43 billion.

The Detroit automaker increased its guidance for the year of adjusted earnings to be in a range of $12.5 billion to $14.5 billion, up from $12 billion to $14 billion. The automaker expects its net income for ...Read more

Honda nears deal with Canada to boost electric vehicle capacity

Canada is on the verge of an agreement with Honda Motor Co. that would see the Japanese firm build electric vehicles and their components in the province of Ontario, according to people familiar with the matter.

The deal, expected to be announced within a week, involves a multibillion-dollar commitment by Honda for new facilities to process ...Read more

Elon Musk and Tesla: Is the CEO's controversial behavior responsible for company's struggles?

The richest man in the world says and does what he wants. And often, it’s contentious and provocative.

Tesla CEO Elon Musk has attacked U.S. election integrity, embraced white-supremacist propaganda and accused President Joe Biden of treason. He even smoked pot on Joe Rogan’s provocative podcast.

Today, the pioneering electric-car company ...Read more

'Keeps the momentum': What the UAW's Volkswagen win means for its organizing campaign

The United Auto Workers’ organizing victory at Volkswagen AG's plant in Tennessee is a critical early momentum-builder as the union turns to more auto and battery plants across the South, experts say, but further successes aren't a foregone conclusion.

The Volkswagen landslide in Chattanooga, where 73% of voting workers backed UAW ...Read more

Motormouth: Benefits of a gentle stop?

Q: I have come across motorists whose brake lights come on hundreds of feet before a stop light. Brake lights come on, the vehicle immediately slows and it eventually comes to a complete stop at the light. Strictly in terms of brake wear, does a gentle stop over a long distance and time wear out the brakes less than a firmer stop (no skid marks)...Read more

China's highflying EV industry is going global. Why that has Tesla and other carmakers worried

TAIPEI, Taiwan — The U.S.-China rivalry has a new flashpoint in the battle for technology supremacy: electric cars.

So far, the U.S. is losing.

Last year, China became the world's foremost auto exporter, according to the China Passenger Car Association, surpassing Japan with more than 5 million sales overseas. New energy vehicles accounted ...Read more

Georgia demands Rivian secure, maintain factory site

Electric vehicle maker Rivian said it is working to secure and maintain the site of its planned Georgia factory, as well as preparing the land for vertical construction as soon as it can move forward with the $5 billion project.

Letters exchanged by Rivian and lawyers for the state of Georgia and a local joint development authority show the ...Read more

Tesla co-founder JB Straubel has built an EV battery colossus

In the scrublands of western Nevada, Tesla co-founder JB Straubel stood on a bluff overlooking several acres of neatly stacked packs of used-up lithium-ion batteries, out of place against the puffs of sagebrush dotting the undulating hills. As if on cue, a giant tumbleweed rolled by. It was the last Friday of March, and Straubel had just struck ...Read more

How Ford's most profitable business is defying the EV slump

While malaise sets in across much of the electric vehicle market, there’s a corner that’s still going strong, where buyers like Chris Russo show little concern about high prices or range anxiety or spotty charging infrastructure.

The co-founder of Elite Home Care, a South Carolina-based company, bought his first EV more than two years ago �...Read more

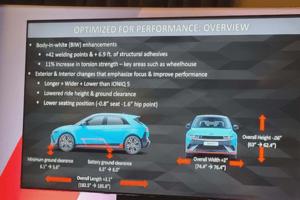

Auto review: Flat out in the Hyundai Ioniq 5 N electric track rat

LAGUNA SECA, California — Out of slow, 90-degree Turn 11 onto the Laguna Seca Raceway’s pit straight, my 2025 Hyundai Ioniq 5 N performance SUV instantly put down 545 pounds of torque and 601 horsepower to all four fat Pirelli P Zero performance tires. No downshift to second gear. No turbo lag. Just pure thrust. Zot! Seconds later, the EV ...Read more

Auto review: 2024 Lexus TX PHEV displays beauty and luxury

You heard it here first! As a Volvo fan myself, I don't see a lot of manufacturers that do it better, as the competition seems to always be chasing Volvo’s design, comfort and pricing. But with Lexus sharpening their pencil, we may have ourselves something here. I give you the 2024 Lexus TX550h+ Luxury.

This six-passenger hybrid SUV takes a ...Read more

Auto review: Two new Toyotas sure to satisfy your soul

Toyota has long been America’s favorite automaker, even if it hasn't always topped the sales charts. Certainly, it’s the world’s largest auto manufacturer, a spot once claimed by General Motors. So, when Toyota introduces two new models, it’s certainly big news. Better yet, along with the news came the chance to briefly experience both ...Read more

'This feels totally different': For 3rd time, VW workers mull joining UAW

CHATTANOOGA, Tennessee — Some are betting they will make history this week as Volkswagen AG workers vote on whether to join the United Auto Workers in this southern auto-producing state, where a right-to-work law is ingrained in its constitution.

Those pushing for unionization at the sprawling plant surrounded by the mountains of East ...Read more

Mercedes-Benz workers to vote on whether to join the UAW in May

Employees at Mercedes-Benz Group's assembly and battery plants outside Tuscaloosa, Alabama, will vote whether to join the United Auto Workers from May 13-17, the National Labor Relations Board said Thursday.

The election will be the Detroit-based union's second at a foreign-owned assembly plant following the launch of its $40 million organizing...Read more

Construction paused at VinFast's NC site as carmaker seeks a smaller footprint

Nearly nine months after VinFast broke ground on its planned $4 billion electric vehicle factory in North Carolina, construction at the Chatham County site has stalled while local officials await updated building plans from the Vietnamese carmaker.

Chatham County confirmed Tuesday what News & Observer drone footage makes clear: No significant ...Read more

Tesla asks investors to approve Musk's $56 billion pay again

Tesla Inc. will ask shareholders to vote again on the same $56 billion compensation package for Chief Executive Officer Elon Musk that was voided by a Delaware court early this year.

In its proxy filing issued Wednesday, Tesla also said it will call a vote on moving the company’s state of incorporation to Texas from Delaware. The carmaker ...Read more