Current News

/ArcaMax

UCLA's top cop, accused of security lapse, faces calls to step aside. He defends his actions

LOS ANGELES — The UCLA police chief is facing growing scrutiny for what three sources told the Los Angeles Times was a string of serious security lapses before a mob attacked a pro-Palestinian student encampment this week.

But the chief, John Thomas, late Friday rejected those allegations and said he did “everything I could” to provide ...Read more

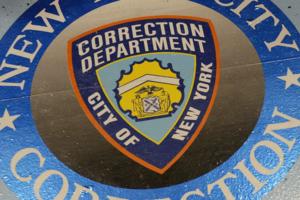

City Dept. of Correction pulls all body-worn cameras after one ignites, injures captain

NEW YORK — The city Department of Correction temporarily pulled almost 3,500 body-worn cameras after one caught fire and injured a correction captain, the department said Saturday.

The captain was on duty in the George R. Vierno Center on Rikers Island Friday when her Reveal Media D5 body-worn camera spontaneously ignited, said department ...Read more

Bay Bridge to be relit, with twice the lights

In the decade after they went up, the 25,000 LED lights illuminating the western side of the Bay Bridge endured a brutal pounding.

“It’s the salty air, the wind, the fog, the rain, the 24-7 vibrations on the bridge, lightning strikes, car grit and grime — and more,” said Ben Davis, founder of the San Francisco nonprofit behind the light...Read more

'Stop funding genocide': Boise protesters call for ceasefire in Gaza, set up encampment

BOISE, Idaho — Dozens of people came out to protest in Boise on Friday night and into Saturday calling for an immediate and permanent ceasefire in Gaza.

The demonstrations come amid growing antiwar protests and as students nationwide form encampments on college campuses to call for their universities to divest from companies with links to ...Read more

Sullivan says US-Saudi defense pact not possible without Israel deal, Financial Times reports

U.S. National Security Adviser Jake Sullivan insisted the Biden administration will enter into a defense pact with Saudi Arabia only if the kingdom normalizes relations with Israel, the Financial Times reported.

Sullivan said in an interview with the newspaper the two issues were part of an “integrated vision” for peace in the Middle East ...Read more

Labour mayor wins cap triumphant election run for Starmer

Labour wins in the U.K.’s two biggest cities completed a string of local election successes by opposition leader Keir Starmer that showed his party firmly on course for victory at a general election later this year.

Not only did Sadiq Khan comfortably win a historic third term as London mayor, but Labour candidate Richard Parker eked out an ...Read more

Yellen counsels caution on currency intervention after yen surge

U.S. Treasury Secretary Janet Yellen acknowledged sharp moves in the value of the yen this week, even as she declined to say whether Japan had intervened to support the currency.

“I’m not going to comment on whether they did or didn’t intervene,” Yellen told reporters Saturday following a speech in Mesa, Arizona. “I think that that’...Read more

Boaters dumping trash in South Florida's waters? Teens face felony charges

MIAMI — Two teen boaters are facing felony charges for pollution after they were caught on video dumping trash into the Atlantic Ocean during a South Florida boating party.

The 16-year-old and 15-year-old boys from Palm Beach County were arrested Friday about a week after a drone video of the illegal dumping went viral online, according to ...Read more

A seized superyacht shows up in Pacific Northwest -- minus one Russian oligarch owner

EVERETT, Wash. — It's not clear whether Russian oligarch Suleiman Kerimov had plans to visit Puget Sound this spring — the French Riviera is more the style of the U.S.-sanctioned mining and energy multibillionaire.

But on April 29, the Amadea, a 348-foot, $300 million-plus superyacht said to be owned by Kerimov, arrived in the Port of ...Read more

Buffett says US corporate taxes likely to rise to tame deficit

WASHINGTON — U.S. taxes are likely to rise as lawmakers look to narrow the federal deficit, Warren Buffett said, as Washington prepares for major tax negotiations next year.

The Berkshire Hathaway chairman and chief executive officer, speaking Saturday at the company’s closely watched annual meeting in Omaha, sidestepped directly commenting...Read more

UK, Ireland leaders on collision course over migration surge

A dispute between the U.K. and Ireland over a surge in asylum-seekers is threatening to upend their already fragile relationship. With elections on the horizon for the leaders of both countries, neither side appears likely to back down.

Disagreements between Prime Minister Rishi Sunak and his newly installed Irish counterpart, Taoiseach Simon ...Read more

Labour on course for power: 5 takeaways from UK elections

The governing Conservatives suffered heavy defeats in a set of local elections on Thursday, adding to the sense that Prime Minister Rishi Sunak will struggle to turn things around before a general election that he must hold within nine months.

Keir Starmer’s opposition Labour Party made some eye-catching gains, taking control of councils in ...Read more

Togo's initial vote count shows family dynasty on track to extend 57-year rule

Togo’s ruling party opened up a commanding lead as the vote count from this week’s parliamentary vote passed the half-way mark, setting the stage for the family dynasty of President Faure Gnassingbé to extend its 57-year rule of the West African nation.

Gnassingbé’s Union for the Republic party won 60 out of the 65 seats for which ...Read more

Labour mayor wins cap triumphant election run for Keir Starmer

Labour wins in the U.K.’s two biggest cities completed a string of local election successes by opposition leader Keir Starmer that showed his party firmly on course for victory at a general election later this year.

Not only did Sadiq Khan comfortably win a historic third term as London mayor, but Labour candidate Richard Parker eked out an ...Read more

Eight arrested in multimillion-dollar retail theft operation, LA County sheriff's officials say

LOS ANGELES — Eight people have been arrested on suspicion of organized retail theft after authorities discovered several million dollars' worth of stolen medicines, cosmetics and other merchandise at multiple Los Angeles locations, L.A. County sheriff's officials announced this week.

The retail goods were stolen by crews of organized ...Read more

Bodies found in Baja California during search for missing tourists, Mexican officials say

MEXICO CITY — Mexican officials said three bodies have been found in the same remote stretch of Baja California where two Australian brothers and their American friend went missing last week while on a surf trip.

The bodies were recovered south of the city of Ensenada, according to a statement from the state prosecutor's office. The statement...Read more

Tufts encampment protesting Israel comes down, but demonstrators vow to continue fight

BOSTON — The protest encampment at Tufts University has come down, but the students who put up the tents say they will continue to fight until the school fully divests from Israel.

Tufts Students for Justice in Palestine, which set up the tents in early April, removed the encampment on the academic quad Friday night after failing to reach a ...Read more

Is the NYPD too political? Cops drive Gaza protest narrative with slick video of Columbia raid

NEW YORK — The video begins over ominous music in a New York City Police Department command center with top brass mulling over surveillance video of a man waving a Palestinian flag and ends with police officials talking tough about their crackdown on protesters at Columbia University Tuesday night.

“The conditions in this courtyard are ...Read more

Group of students call for University of Michigan to divest from Israel at commencement, but speeches continue

ANN ARBOR, Mich. — A group of about 50 graduating students stood and called for the University of Michigan to divest from companies with ties to Israel at the spring commencement ceremony Saturday, but the speeches continued.“Disclose! Divest! We will not stop, we will not rest!” students chanted early in the ceremony at the Big House in ...Read more

Police use chemical spray, handcuff protesters, arrest nonstudent outside University of Michigan museum

ANN ARBOR, Mich. — Police used a chemical spray to disperse a large crowd and handcuff pro-Palestinian protesters during a chaotic scene outside the University of Michigan Museum of Art on Friday night, according to videos posted on social media.

The incident occurred around 9 p.m. outside the museum on South State Street in downtown Ann ...Read more

Popular Stories

- Use of ‘white privilege’ makes online discussions more polarized and less constructive

- Beer and spirits have more detrimental effects on the waistline and on cardiovascular disease risk than red or white wine

- Before mob attack, UCLA police chief was ordered to create security plan but didn't, sources say

- Cinco de Mayo: You might be surprised how long it's been celebrated in the U.S.

- In election year, US Rep. Mary Peltola walks a complicated path on fisheries and oil drilling