Politics

/ArcaMax

Justice Thomas criticizes 'nastiness and the lies' he faces

U.S. Supreme Court Justice Clarence Thomas decried “the nastiness and the lies” he and his wife Ginny have “had to endure” in recent years.

“There’s certainly been a lot of negativity for my wife and I in the last few years,” Thomas said Friday at a conference of the US Court of Appeals for the 11th Circuit in Point Clear, Alabama...Read more

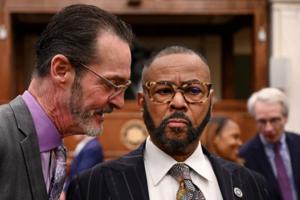

Georgia Republicans boot vice chairman after ruling he voted illegally

ATLANTA — The Georgia Republican Party voted overwhelmingly Friday to oust First Vice Chairman Brian K. Pritchard from his leadership position after a judge ruled he voted illegally nine times while serving probation for a felony check forgery sentence.

The decision by 86% of the Republican Party’s state committee removes Pritchard, a ...Read more

Release of Alberto Fujimori in Peru rekindles fears of backsliding on human rights

The release from prison of former Peruvian president Alberto Fujimori on Dec. 6, 2023, has sparked concern over Peru’s commitment to human rights.

The move came a a day after the Constitutional Tribunal of Peru ruled that the 85-year-old, who was serving a 25-year sentence for crimes against humanity, be freed on humanitarian and ...Read more

Trump vows to reverse Biden protections for trans students 'on day one'

Former President Trump Friday vowed to roll back protections for transgender students “on Day One” if he wins the November election.

The ex-president told a conservative radio show that he would reverse an order recently enacted by President Biden that would prohibit discrimination in education on the basis of sexual orientation or gender ...Read more

Judge in Trump hush money trial directs DA to get key witness Michael Cohen under control

NEW YORK — As the Donald Trump hush money trial wrapped up for the week Friday, New York Supreme Justice Merchan warned the DA to get Trump’s fixer-turned-foe Michael Cohen to dial back his posting on social media about Trump and the case.

Cohen has been outspoken about his feelings on his former boss ahead of his expected appearance next ...Read more

Millionaires making election moves in Maryland, Nebraska and West Virginia

WASHINGTON — Tuesday’s primaries feature a multimillionaire House member and and a multimillionaire governor vying for open Senate seats in Maryland and West Virginia, while a multimillionaire Nebraska senator is funding a super PAC to aid a potentially vulnerable House colleague.

Of course, money does not guarantee success, and the ...Read more

Jon Stewart rips 'nonstop penis-to-penis coverage' of Trump hush money trial

NEW YORK — Leave it to Jon Stewart to put Donald Trump’s hush money trial into a very unique perspective.

The Emmy Award-winning funnyman ripped the obsessive media coverage of testimony from porn star Stormy Daniels during the former president’s New York City court proceedings this week.

“It has been another big week of wall-to-wall, ...Read more

Georgia sees drop in medical resident applicants after Supreme Court abortion ruling

ATLANTA — After the U.S. Supreme Court’s Dobbs decision in June 2022 allowing states like Georgia to institute abortion bans, states with abortion bans or restrictions started attracting fewer medical residents, the new doctors who work in training at academic hospitals.

Court decisions in 2022 and 2023 including by Georgia’s state ...Read more

Trump response to sex tryst allegations key focus as hush money trial resumes

NEW YORK — A bid by Donald Trump’s lawyers to show he was concerned about how his family would take the news of the Stormy Daniels sex tryst allegations fizzled Friday as testimony in the ex-president’s hush money trial resumed.

Former top White House aide Madeleine Westerhout, who famously lost her job after saying she had a better ...Read more

2 Florida men, 1 ticket? A Trump, Rubio pairing brings tricky political, legal questions

ORLANDO, Fla. — U.S. Sen. Marco Rubio once called Donald Trump a “con artist” too “dangerous” and “erratic” to be entrusted with nuclear codes. But in a few months, Rubio could be calling Trump something else: his running mate.

The Florida Republican was one of a few people on Trump’s vice presidential shortlist who attended a ...Read more

I’ve spent decades overseeing relief operations around the world, and here’s what’s going wrong in Gaza

Amid persistent calls from the United States and other countries that Israel needs to make it easier for life-saving aid to reach Palestinians in the Gaza Strip, the Israeli military closed two of the region’s few operating border crossings in Rafah, a southern Gazan city, on May 7, 2024.

Responding to political pressure and alarm, ...Read more

Congressional committee to hold hearing on Key Bridge response efforts as funding fight continues

BALTIMORE — As Maryland leaders push for the federal government to cover all future expenses related to the Francis Scott Key Bridge, members of Congress will hold a hearing Wednesday regarding the response efforts.

The U.S. House Committee on Transportation and Infrastructure hearing will focus on the federal agencies that have led the ...Read more

Donald Trump and Wildwood officials have one major thing in common: Indictments

Wildwood and Donald Trump. Clout can't think of a more fitting pair.

A boardwalk renowned for its collection of politically incorrect T-shirts is about to get flooded with people who would love a "Let's Go Brandon" cut-off tank.

And Trump, who is facing federal indictments in four jurisdictions, is about to rally in a town where two of the ...Read more

A jacket, a coin, a letter − relics of Omaha Beach battle tell the story of D-Day 80 years later

Between the villages of Vierville-sur-Mer and Sainte-Honorine-des-Pertes in Normandy, France, is a 5-mile stretch of beach that was once called Côte d’Or, or “golden coast.”

Since June 6, 1944, however, this beach has borne a different name: Omaha.

Eighty years ago, on a day now known as D-Day, thousands of Allied ...Read more

High court's immunity ruling may not save Trump in Georgia

ATLANTA — If the U.S. Supreme Court rules that Donald Trump cannot be prosecuted for acts he took as part of his official duties, his Atlanta lawyers are expected to argue that would strip away much of the Fulton County case against the former president.

But it is also possible such a decision won’t make much of a difference to the election...Read more

Sudan’s descent into chaos sets stage for al-Qaida to make a return to historic stronghold

“Sudan’s moment has come; chaos is our chance to sow the seeds of jihad,” warned Abu Hudhaifa al-Sudani, a high-ranking al-Qaida leader, in an October 2022 manifesto.

His words may have seemed premature at the time, but a year of brutal civil war has now plunged Sudan into the kind of chaos in which terrorist groups thrive. The ...Read more

'Are you a Zionist?' Checkpoints at UCLA encampment provoked fear, debate among Jews

LOS ANGELES — Eilon Presman was about 100 feet from the UCLA Palestinian solidarity encampment when he heard the screams: "Zionist! Zionist!"

The 20-year-old junior, who is Israeli, realized the activists were pointing at him.

"Human chain!" they cried.

A line of protesters linked arms and marched toward him, Presman said, blocking him ...Read more

Biden prods Boeing to end impasse with firefighters union

President Joe Biden weighed in on a labor dispute underway at Boeing Co., urging the planemaker to restart stalled contract talks with a union representing 160 of its firefighters.

“Collective bargaining is a right that helps employers and employees,” Biden said in a post on X, the social media site formerly known as Twitter. He said he was...Read more

Fetterman slams Biden over threat to withhold some arms supplies to Israel, calling it 'deeply disappointing'

U.S. Sen. John Fetterman called President Joe Biden's threat to withhold military aid to Israel "deeply disappointing," the latest criticism he has levied at the president over his handling of the war in Gaza.

On Wednesday, Biden announced on CNN that he would halt some shipments of bombs and artillery into Israel if the country invaded the ...Read more

Biden administration wants to speed up deportation for some migrants. How will it work?

WASHINGTON — The Biden administration proposed a rule Thursday aimed at speeding up the deportation process for migrants who are already ineligible for asylum.

The change isn't expected to have broad implications, but rather tighten existing rules. It comes as the White House and Democrats play offense on the border and immigration, one of ...Read more

Popular Stories

- Did Stormy Daniels' testimony help or hurt the case against Trump? It's complicated

- Analysis: What could appeal of Fani Willis fight mean for Fulton Trump case?

- Supreme Court to decide contentious issues amid ongoing criticism

- Moskowitz uses taxpayer-funded mailer to distance himself from unpopular Biden border policies

- A jacket, a coin, a letter − relics of Omaha Beach battle tell the story of D-Day 80 years later